My purpose in central Oregon over the summer was to collect seed. Specifically, as much seed as possible from species that have never been collected before. I needed a minimum of 10,000 seeds for the seed bank, and a surplus of 30,000+ seeds for restoration projects across the district. Our district database has 255 species that have already been collected, so those 255 species were off limits – I had to find something else to collect.

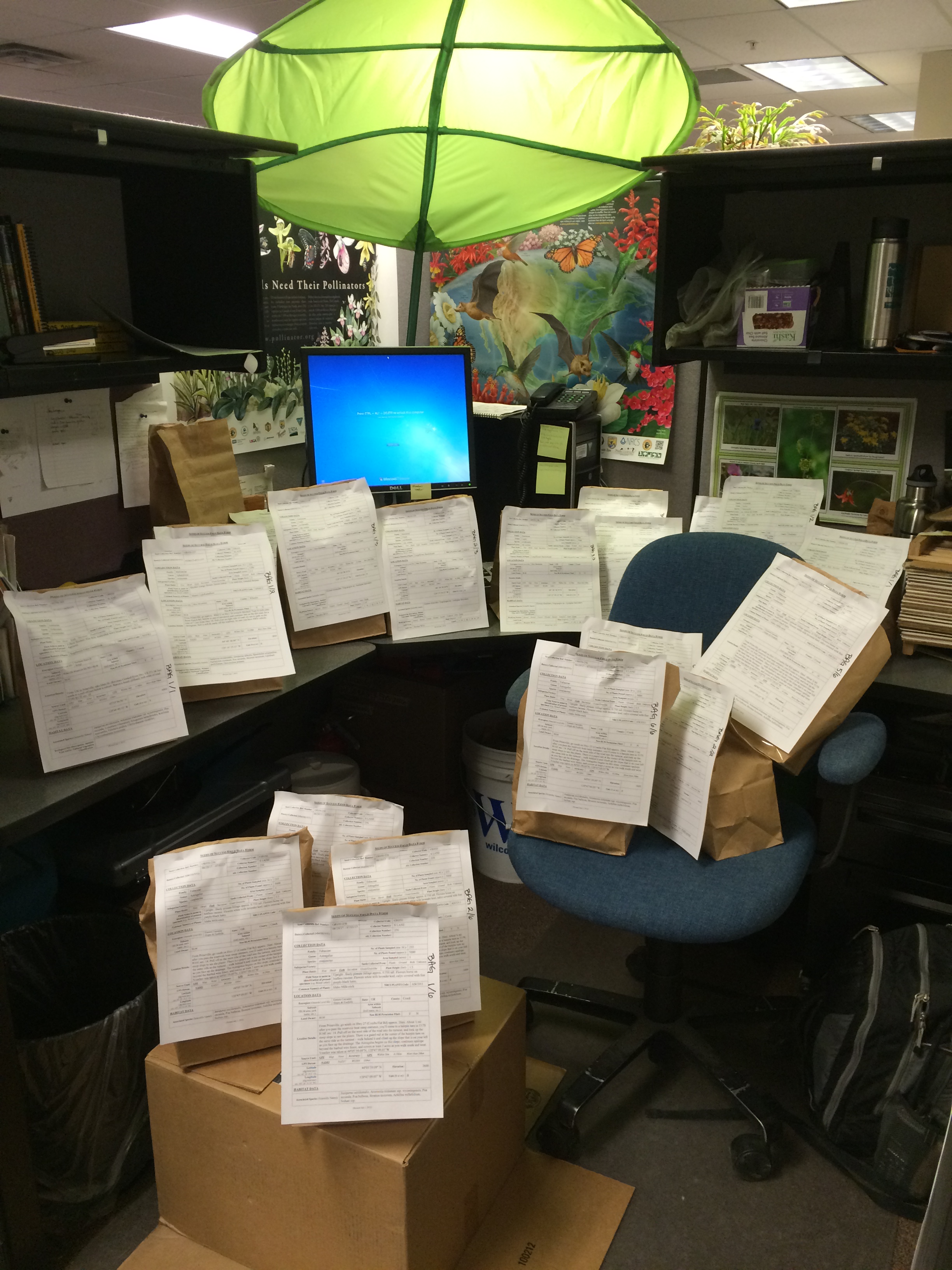

Within a few months of starting my seed collection mission, I had 10 new species in the bag (literally). But all that seed takes up space, and my cubicle was starting to get a little cramped.

Mapping, monitoring, and collecting 50,000+ seeds for a single species: 40 work hours.

So, what do you do with all that seed? It has to get cleaned, sorted, tested for viability, packaged, and stored properly so it doesn’t get contaminated or expire. Enter: The Bend Seed Extractory!

The Bend Seed Extractory is a facility owned and operated by the US Forest Service in Bend, OR. They receive, catalog, clean, test, and store all the seed that we Conservation & Land Management Interns collect and send to them. The facility houses equipment designed and built over the years by Forest Service engineers, as well as specialty equipment crafted in Denmark specifically for seed cleaning. On my first trip to the extractory I got a tour from Sarah Garvin, Assistant Manager and former Conservation & Land Management Intern.

Custom equipment built expressly for seed cleaning: decades of work by ingenious engineers

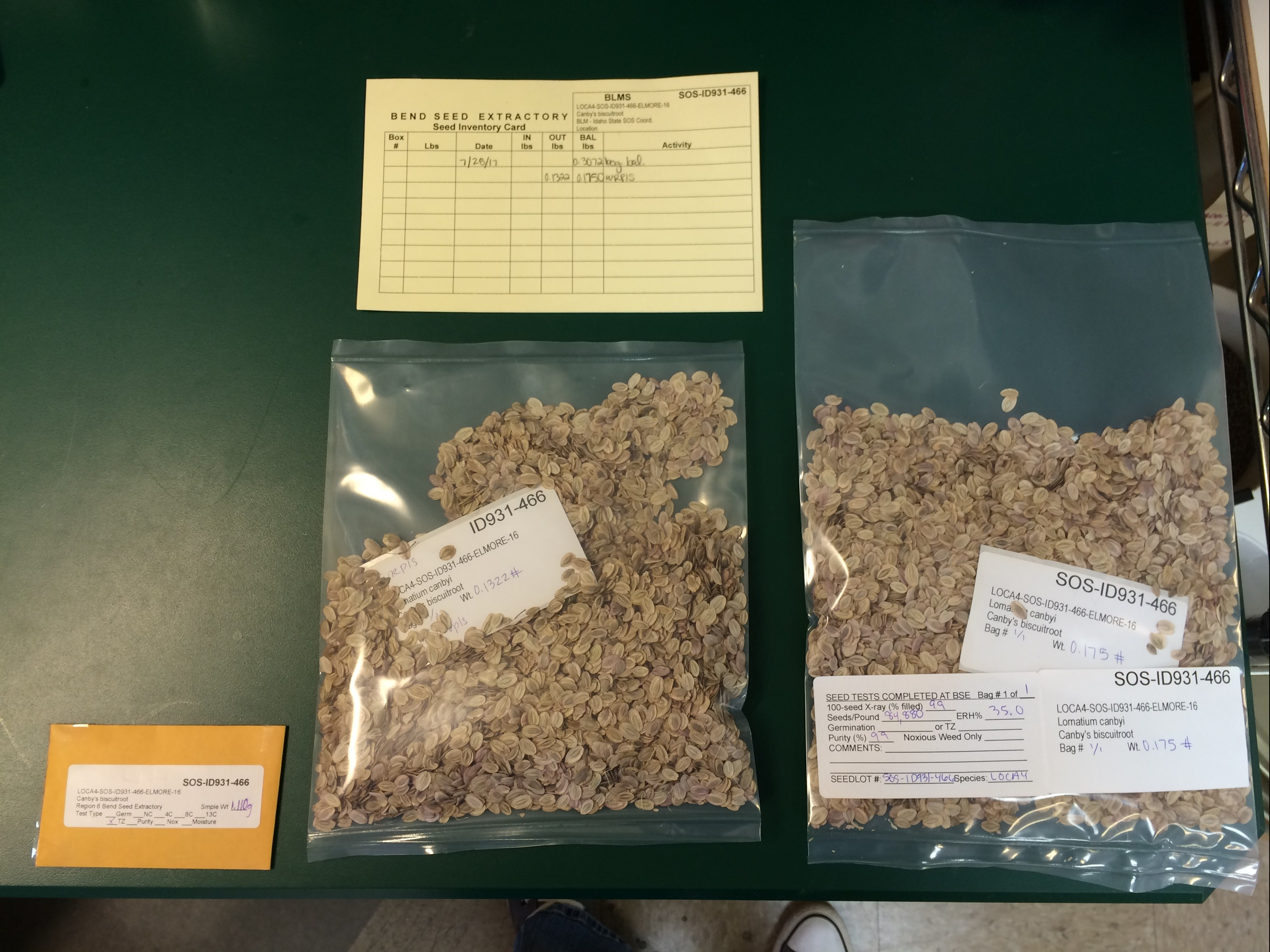

Whenever we ship seed to Bend, they receive the shipment into a catalog system like a library. Each collection is identified by the unique code and collection number for the sending office.

One week’s worth of seed shipments from across the US: I estimate 4,500 work hours

I got to see boxes of a yucca species shipped from the crew in Nevada – good work, Nevada team! Your 70 lb boxes of seed were impressive!!

- Pods of Yucca seed, fresh from the field

- 70 lbs!! I admire whoever had to carry that…

Next begins the time-consuming process of figuring out how to clean all the seed. There is no set protocol for a given species because different methods of collection create different challenges for cleaning. For example: a grass seed that arrives still attached to the stem is a different process than grass seed that was stripped clean off the stem.

The seed techs at the extractory know what each piece of machinery is capable of, and what technique it is best used for. They look at each collection like a puzzle, and develop a cleaning method for each and every collection that comes through the warehouse. It might be as simple as sifting the seed through a screen, or using a variety of machines in succession to separate stems, chaff, damaged seed, and good seed.

- Pine seeds separated from cone scales by hand

- This machine has a vacuum hose to remove dust and chaff

- This conveyer belt has multiple types of screens to separate different waste materials at different stages

My favorite machine was the gravity table. The table can be adjusted at an angle so that the heavy seeds will roll faster down the steeper slope, while the lighter chaff and poor-quality seed runs down the flatter part into a waste bin.

- Gravity table for separating seed

- Seed coming down the line: the heavy black seed rolls to the back, while the lighter chaff stays closer to the front

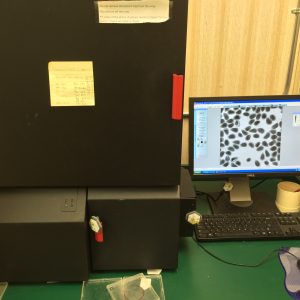

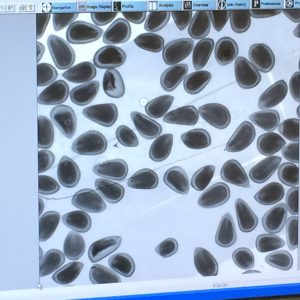

Once the seed has gone through a basic cleaning, it’s time to see what sort of quality you get. The seed gets an x-ray to determine whether the embryo inside is fully formed, or if they were duds. Sometimes a seed can look right on the outside, but their insides haven’t developed properly.

- The black box is the X-ray machine – the seeds go inside on a dish

- The X-ray results are viewed on the monitor. Dark seed is good! There are a couple seeds that look like a bubbles that didn’t develop properly.

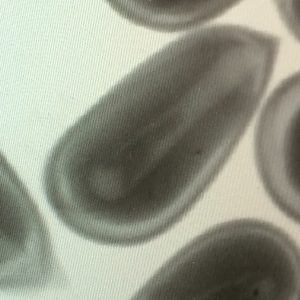

- This is a pine seed. Inside you can see the embryo – the light rod with the Y shape at one end are the cotyledons! This tree is ready to grow 🙂

Depending on how the seed looks, it might go back out for another separation cleaning to filter off poor-quality seed. Again, gravity is our friend. The gravity table shown below is much more sensitive, and has the ability to separate out seed into as many as 5 qualities. This means that you can be sure the heaviest seed is the highest quality, and you can then examine the other assortments for their quality and discard the poor-quality seed.

This gravity table will sort seed with a fine sensitivity. It’s great for very tiny seeds, or seeds of mixed quality.

Once quality is under control, the seed goes for a final round of fine-cleaning before packaging. The second cleaning, or “finishing” phase, is to ensure that the vast majority of content is seed and only seed. This eliminates the fine dust, chaff, and damaged seed from the seed lot. The machines in this step are similar to the ones in the initial cleaning, except smaller and more sensitive.

This machine uses an air column to blow fine dust and chaff up into a collection bin while the polished seed falls to the bottom into a collection container.

- Clean, viable seed, waiting for packaging.

- This much clean, live seed from field to bucket: approx. 100 work hours

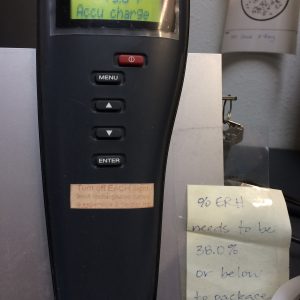

Finally, the seed is ready to be packaged! It’s stored at low humidity and 100 seeds are counted out by hand to determine the number of seeds per ounce. Any remaining plant material is picked out by hand to ensure no inert weight is included in the seed lot. By hand, people, no more machines.

- A relative humidity monitor lets you know if it’s a good day to package seed. Max humidity is 38%, today it reads 37.4%!

- Weighing and packaging a seed lot: approx. 2 work hours

Now is the moment when our precious seed is divided into its three final packages: one sample packet goes to Oregon State University for confirmation of the pure live seed count, one packet of 10,000 seed goes to the Seeds of Success conservation bank, and the remainder is stored in the Bend Seed Extractory refrigeration unit until a field office requests the seed for restoration projects.

Remember all the bags in my office? Hopefully this is what each one will look like after the crew at the extractory gets done with them:

Saving the seeds: priceless.